efficiency increased by almost 20%

final waste limited to just 10%

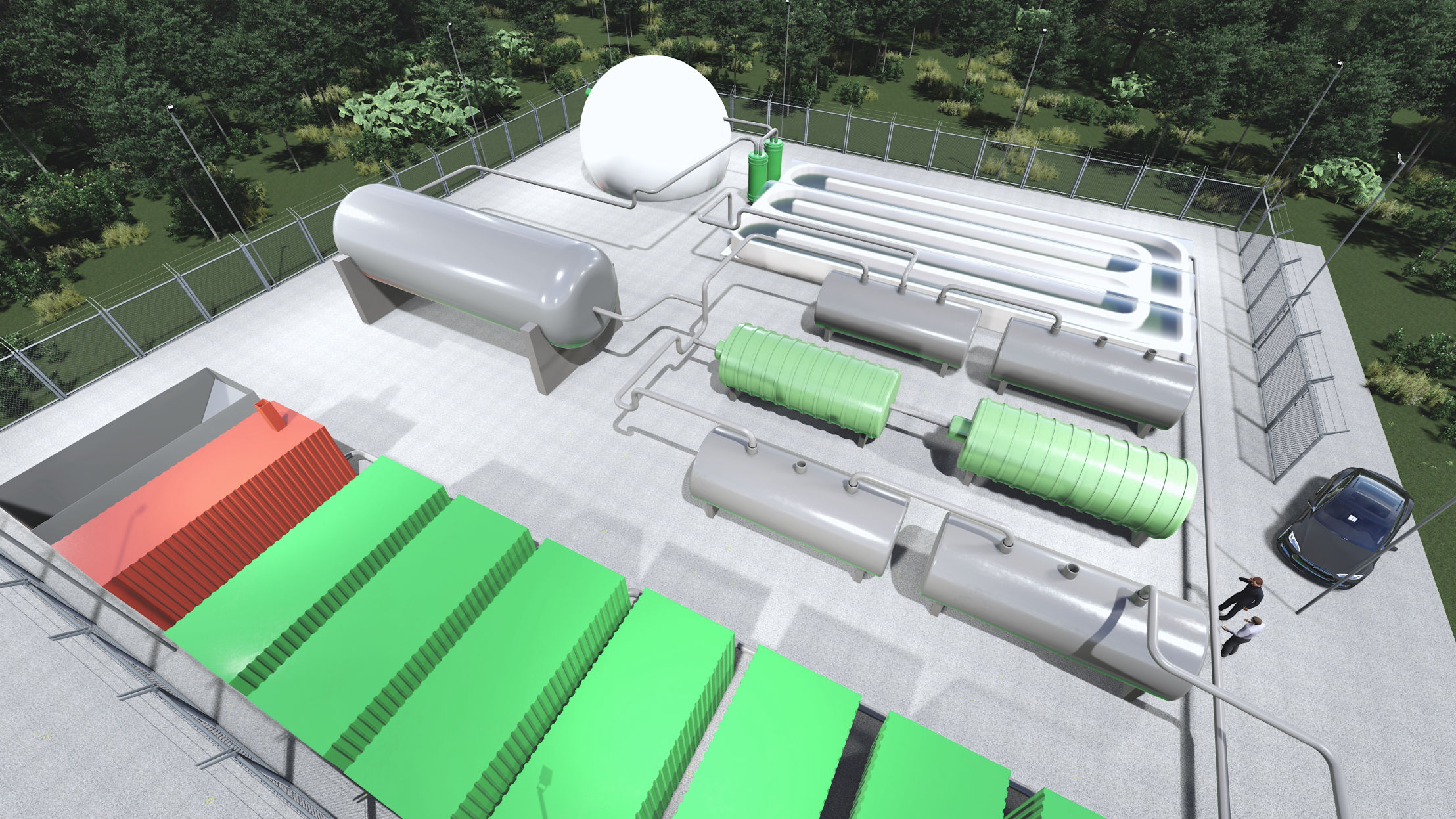

The installation is a module consisting of a group of containers connected in a technological line. With little cost, it can be relocated to any other place or the proportions of individual containers for a specific substrate can be changed.

This allows for scaling the size and thus the power of the entire installation, and thanks to their mobility, we obtain optimal location in the field without being forced to carry out construction works.

In addition, at the customer's request, the containers are equipped with HDS transport handles, which allows them to be transported to the place of loading and then easily reattached.

The process of biogas production itself takes place in several stages, which is why individual groups of containers fulfill strictly defined functions. This allows for the control of hydrolysis and methanogenesis processes thanks to the possibility of their independent monitoring and control.

Conventional biogas plants operate on the basis of very capacious fermentation tanks, where methane production processes take place in one volume, not allowing for free selection of substrates or control of the decomposition process.

In our solution, the AI-based system is able to adjust the processes distributed between containers for the best optimisation depending on the supplied substrates and suggests their best mixes. Thanks to this, we use a wide range of raw materials of animal and plant origin as well as municipal or shop waste.

The system managing the entire installation is based on artificial intelligence, thanks to which it is able to learn and optimise processes for the best efficiency.

Disabling individual containers for repair or maintenance does not disturb the operation of the entire process, and the communication of modules within the distributed Mesh network with acquisition to the data cloud allows you to remotely analyse their status and operation.

In addition, thanks to the innovative combination of additional processes, waste in the form of fertilizer does not exceed 10% of the initial dry weight.

The solution of Polski Biogaz is an evolutionary development of the technologies used so far, and thanks to the synergistic approach to the issue, it guarantees the achievement of much greater energy efficiency compared to classic solutions, which directly translates into an economic advantage.

No permanent connection to the ground, minimising the number of connections and transferring the burden of data processing to the cloud minimises the number of necessary permits and the cost of the investment itself. The classic installation is usually "concrete bunkers" where the construction process and the process start-up are counted in years. This generates incomparably higher costs at the stage of permits, investments and service.

SAMPLE CONFIGURATION

Each container is equipped with a quick loading and unloading system and can be easily transported. Thanks to that we can avoid unnecessary problems with loading of the substrates. Smaller-sized containers in larger quantities compared to powerful concrete tanks for the same power, reduce downtime costs for maintenance or repairs, because excluding a single container from circulation does not stop the process.

How do our mobile biogas plants differ from competitors' solutions?

All processes take place within one tank, which means that in the event of repairs or maintenance, it is necessary to stop the operation of the entire installation

PBG

Individual groups of containers perform strictly defined functions, which allows for better control and optimisation, and the shutdown of individual containers for maintenance does not interfere with the operation of the entire installation

Adapted to a specific narrow group of substrate

(in practice mainly maize and slurry) it prevents the use of full seasonality of substrates, which means that a large amount of potential biomass remains unused

PBG

Thanks to AI solutions, the system is able to adjust the processes distributed between containers for the best optimisation depending on the supplied substrates and suggests their best mixes

Waste in classic biogas plants, depending on the dry mass, oscillates between 35% and 50% and is associated with onerous management processes

PBG

Thanks to the innovative combination of additional processes, waste in the form of fertilizer does not exceed 10% of the initial dry matter

*Tiles marked "PBG" refer to the technology of Polski Biogaz

Biogas is biomethane obtained from a renewable energy source, obtained after purification of CO2. It has the parameters of natural gas and can be produced from many sources. The spectrum of substrates is extremely wide and includes virtually all residues and post-production waste of farms, processing plants and slaughterhouses. It can also be derived from almost any product containing organic components of food waste, plant waste and wastewater treatment plants.

There may be as much as 150 million tons of waste to be managed by the industry annually. Appropriate processing should yield about 15 billion m³ of biogas.

According to the report of the Polish Economic Institute "Development and potential of renewable energy in Poland", Biogas and Bio-methane would be able to provide up to 30% of Poland's energy demand.

Biomass is a stable source and thanks to low conversion costs, it can complement other renewable energy sources.

In addition, unlike solar or wind energy,

we are not dependent on weather conditions and the storage of energy in the form of gas is much simpler and cheaper.

Our biogas plants reduce anthropogenic pressure on the environment through the effective management of many harmful substances.

Instead of the cost of disposing of our agricultural waste, food waste or even sewage, we are able to additionally generate income while protecting our environment.

To get to know the offer and possibilities of our biogas plants better, please contact our specialists

POLSKI BIOGAZ LIMITED LIABILITY COMPANY